Fluid solutions for flow batteries

In 1974, scientist L.H. Thaller proposed a revolutionary electrochemical energy storage technology, the flow battery. Compared with conventional batteries, the greatest innovation of the flow battery is that the positive and negative electrolytes are stored in an external reservoir. The representative form of this technology is the aqueous organic flow battery, which is the key to today's efficient energy storage means with its high safety and environmental friendliness.

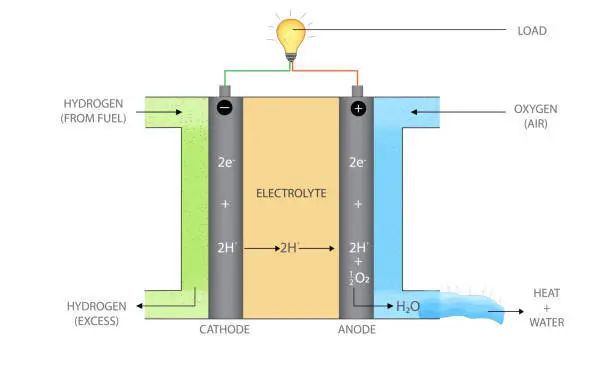

Principle of operation

Flow batteries store and release energy through redox reactions by circulating two solutions in an electrolyte. Among them, aqueous organic liquid flow batteries use water as the medium, demonstrating excellent performance and sustainability. Laboratory pumps play an integral role in the research of liquid flow batteries, supporting the circulation and control of the electrolyte solution.

The following are the main applications of laboratory pumps in flow batteries:

Electrolyte circulation: laboratory pumps ensure that the electrolyte solution is transported from one cell reaction tank to another, maintaining the normal operation of the cell.

Solution Mixing: Used to mix electrolyte solutions of different concentrations or components to maintain the stability and performance of the cell.

Redox Agent Delivery: Delivering oxidizing and reducing agents through the laboratory pump to promote the redox reaction in the battery and achieve energy storage and release.

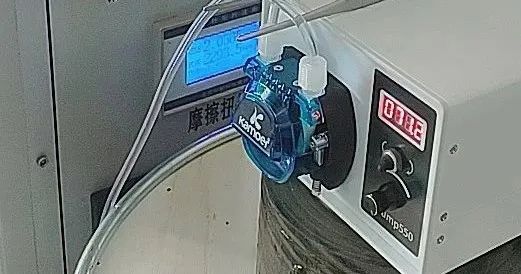

DIP550 Lab pump DIP550 Lab pump

Kamoer provides fluid solutions for several flow battery experiments. The Kamoer DIP 550 lab pump (flow rate: 0-450ml/min) plays a key role in flow battery research and its features include:

Good media compatibility: The Kamoer DIP 550 laboratory pumps have good media compatibility (e.g. sulphuric acid, mixed acid vanadium, ferrochromium, zinc bromide, nickel, iron, etc.), which provides strong support for fluid transfer.

Adapt to special environments: Resistant to low and high-temperature environments (-20℃ to 60℃), engineering plastics are environmentally friendly and reliable, ensuring reliable operation under various working conditions.

Power failure memory function: automatically saves the operating parameters at the last power down, to cope with the experimental workers who did not save the situation in time.

Multiple working modes: support full-automatic cycle, semi-automatic cycle, manual three working modes, easy to operate and fully functional.

Precise control: adopting a stepping motor, the resolution of speed adjustment can reach 0.1 rpm, providing highly precise liquid control.

Multiple control methods: Supports rotary encoders, foot switches, external analog (4-20mA and 0-5V), 485 communication (Modbus), and more.

The support of the Kamoer DIP550 series of laboratory pumps promotes the research and development of liquid flow battery technology. Through the development of functional membrane materials, new energy storage materials, and the study of their application in electrochemical reactions and energy storage, the liquid flow electrochemical liquid current storage system shows great potential in solving the current energy and environmental problems.

In this era of technological innovation, Kamoer laboratory pumps are not only the right hand for research on flow batteries, they are also the pioneers of a new era in energy storage. Through its outstanding performance and advanced technology, the Kamoer lab pump supports scientists in exploring the future of electrochemical energy storage and contributes to the sustainable development of global energy.