Automatic zinc phosphating production line how to transfer media?

With the rapid development of industrial automation, automated zinc phosphating production lines are emerging as the industry's future stars. In this automated industrial upgrade, the automated zinc phosphating production line is a production system that integrates high-tech equipment and intelligent control systems. Through automatic transmission, precise proportioning and efficient chemical treatment, the production line can improve production efficiency while ensuring production quality and realize intelligent upgrading of industrial production.

Automatic zinc phosphating production line is a production system that integrates high-tech equipment and an intelligent control system. The core principles are as follows:

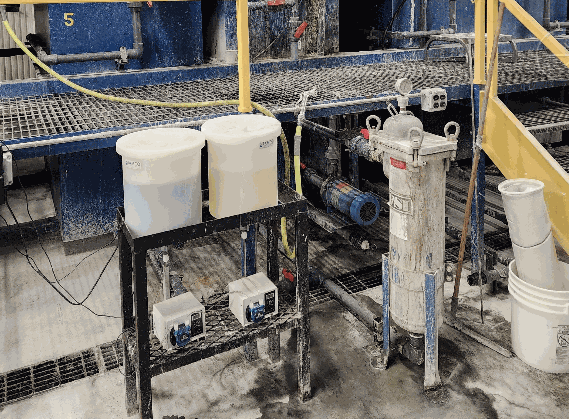

Automatic transmission system

An advanced transmission system delivers chemicals precisely from small plastic tanks to large stainless steel treatment tanks. The automation of this link reduces the intervention of manual operation and improves production efficiency.

Intelligent control and data feedback

The intelligent control system monitors and adjusts the production line in real-time. Various sensors and monitoring devices feed data back to the control system, ensuring every step is carried out under optimal conditions.

Efficient chemical processing

Efficient chemical treatment in large stainless steel treatment tanks to achieve the goal of zinc phosphating. The entire production process does not require too much manual intervention, improving the overall efficiency and consistency of the production line.

DIP550 laboratory pumps stand out in this industrial project with several advanced technologies, the main advantages:

1. Integration of precision control

Through sophisticated liquid control technology and efficient pumping performance, the DIP550 laboratory pump (flow rate: ≤336 ml/min) can accurately transfer chemicals, ensuring that every chemical reaction is carried out under the best conditions and improving the efficiency of the production line.

2. Selection of corrosion-resistant materials

In the zinc phosphating environment, the DIP550 laboratory pump uses corrosion-resistant materials, which can resist the corrosion of the pump such as zinc and phosphorus, ensuring the long life and reliability of the pump.

3. Efficient performance support

DIP550 laboratory pump with its efficient automatic circulation function becomes the production line's right-hand man, to ensure the efficient transmission of the medium, support positive and negative rotation, and speed can be adjusted, and improve the overall efficiency of the production line.

The application of the DIP550 laboratory pump in automated zinc phosphating production line marks the deep integration of science and technology and industry. Its advantages and intelligent application principle not only improve production efficiency but also inject new vitality into industrial production. In the future, we have reason to believe that laboratory pumps will play a more important role in the industrial field, leading the forefront of the automation industry.

Kamoer has many years of experience in fluid applications in medical, environmental, laboratory, and other fields, providing many customers with accurate and reliable fluid transmission solutions, and providing competitive high-quality products for many industry segments. Kamoer will provide comprehensive quality assurance, looking forward to bringing you better service!