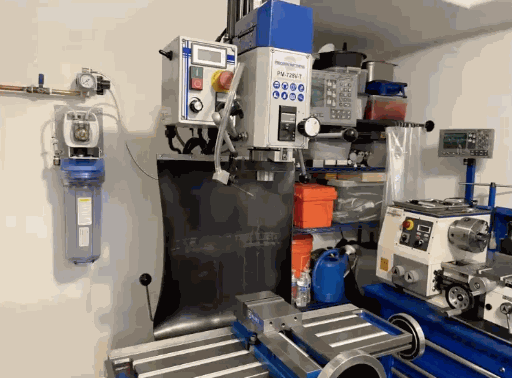

Milling machine cooling system

Milling machine is a kind of precision machine tool, which realizes the processing and forming of parts by cutting the tool on the surface of the workpiece. Its main characteristics include high precision and high efficiency, and it is widely used in aerospace, automobile manufacturing, mold manufacturing, and other industries. Milling machines play a vital role in the manufacturing industry, providing precision and control for the processing of various workpieces.

A milling machine is a commonly used metal processing machine, and its working principle involves cutting the workpiece with the tool:

Clamping workpiece: The operator installs the workpiece to be machined onto the workbench and uses a clamp to ensure the stability of the workpiece during machining.

Select the tool: According to the material, shape and processing requirements of the workpiece, choose the right tool. Different tools can be used for different cutting operations, such as end mills, ball end mills, etc.

Setting cutting parameters: The operator needs to set cutting parameters, including cutting speed, feed speed, cutting depth, etc. The choice of these parameters depends on the workpiece material, tool type, and machining requirements.

Start the milling machine: The operator starts the milling machine and makes it enter the working state.

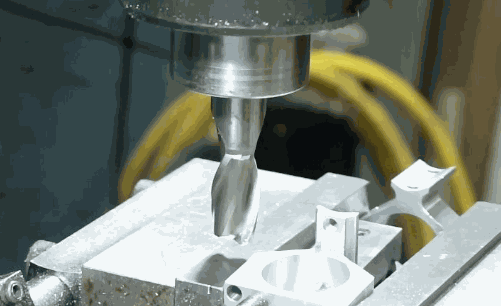

Tool drop: Table and tool start to move. Normally, the tool will start to descend from the surface of the workpiece and enter the cutting area.

Cutting process: The tool cuts by rotation, while the table moves in both horizontal and vertical directions to achieve the cutting of the workpiece. During cutting, the tool removes excess material from the workpiece to form the desired shape and surface features.

Coolant use: To reduce the temperature of the cutting area, prevent overheating, and improve tool life and machining quality, coolant is usually used. Coolant cools tools and workpieces by spraying or flowing.

Finish machining: Once the cutting process is completed, the table stops moving and the tool lifts, the workpiece is finished machining.

The working principle of the milling machine is based on the precise cutting operation, and the operator can realize the precision machining of various workpieces by adjusting different parameters and selecting different tools. This machine tool is widely used in the manufacturing industry, providing efficient and precise machining solutions for production.

In the cutting process of the milling machine, the friction and heat generated between the tool and the workpiece can not be avoided. To ensure that the cutting area maintains a suitable temperature range, coolant is introduced into the system.

The KXP100 lab pump, as the core component in the coolant system of the milling machine, has the following main functions:

-

Stable coolant transfer: The peristaltic principle ensures that the KXP100 pump can steadily and evenly transfer coolant to the cutting area of the milling machine, maintaining temperature control.

-

Buckle connection mode: The unique buckle connection mode simplifies the system installation and maintenance process and improves the ease of operation.

-

Eliminate bubbles: The buckle connection effectively eliminates bubbles that may occur during liquid delivery, ensuring stable coolant delivery.

The excellent application of the KXP100 lab pump in the coolant system of the milling machine provides reliable support for the stable operation and efficient processing of the milling machine through stable liquid delivery, clip connection and bubble elimination. Its superior performance not only improves the efficiency of the system but also simplifies the operation process, bringing a more convenient coolant management experience to the manufacturing industry.

Kamoer has many years of experience in fluid applications in medical, environmental, laboratory, and other fields, providing many customers with accurate and reliable fluid transmission solutions, and providing competitive high-quality products for many industry segments. Kamoer will provide comprehensive quality assurance, looking forward to bringing you better service!