Allegro™ 2D Biocontainer - Powder Port

Integrated into Allegro 2D Single-UseSystems for Mixing Applications

Point of Product

Description

Integrated into Allegro 2D Single-Use Systems for Mixing Applications

Single-use systems have been widely implemented throughout biopharmaceutical processes in many fluid management applications. The main drivers for this are to improve operational flexibility, eliminate cleaning and cleaning validation, improve safety, and ultimately reduce costs by removing non-value added steps from the process and shortening drug development time. Single-use technologies and systems are now available for more advanced applications, such as tangential flow filtration for concentration and diafiltration and in-process mixing.

Features | Benefits |

Biocontainer uses the standard Allegro 2D and 3D biocontainer film | Consistent materials across full range of Allegro biocontainers |

Powder addition port included on biocontainer | Allows for powder to be added into the biocontainer for recirculation mixing |

Inert low density polyethylene (LDPE) fluid contact layer | High clarity and flexibility |

Compatible with a wide range of chemicals | Very low level of extractables and leachables |

No animal derived ingredients | Appropriate materials for biopharmaceutical applications |

Excellent gas barrier properties | Stability of product during storage |

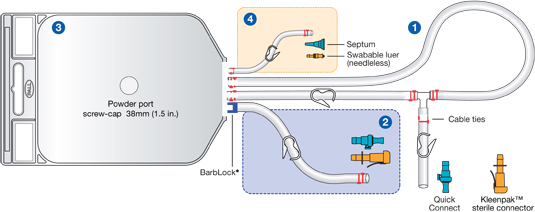

Mixing is an essential operation for any biopharmaceutical process such as mAbs, therapeutic proteins or vaccines. Mixing is applied at multiple stages and for many applications within a process.Typical applications include preparation of buffer and media solutions, control of important fluid parameters such as pH and conductivity around chromatography operations, and final formulation prior to filling.Mixing systems can vary for a wide range of applications and volume sizes. Pall Life Sciences provides a 2-dimensional (2D) pillow-type Allegro biocontainer equipped with a screw cap powder port for single-use mixing system for small volume batches (10 – 50 L). The Allegro 2D biocontainer with powder port can be integrated into Pall Allegro single-use systems to provide mixing using a recirculation method, or for use on an appropriate rocking mechanism. A typical system configuration for recirculation mixing, showing various options for connections is shown below.

Typical System (with Options for Connections) for a Recirculation Set-Up

-

1

Recirculation Loop

(with fluid inlet line)

- Lengths (and connections) defined by application

-

2

Outlet

-

Showing typical connectors used

- Kleenpak™ sterile connector

- Quick connect

-

Showing options for tubing/hose barb connection

- Cable ties

- BarbLock ♦

-

Showing typical connectors used

-

3 Allegro Biocontainer

(with powder port)

- Available in 20 L or 50 L

-

4 Optional Sampling Line

-

Showing options for sampling

- Swabable luer (needleless)

- Septum

-

Showing options for sampling

Specification

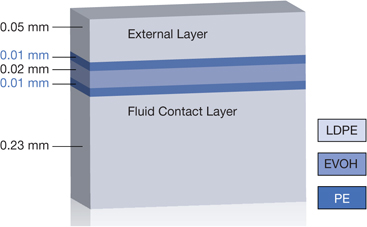

Materials of Construction

- Inner Layer: LDPE

- Oxygen Barrier Layer: EVOH (ethylene-vinyl alcohol copolymer)

- Outer Layer: LDPE

- Fluid Inlet /Outlet /Sample Ports: Polyethylene

- Powder Port: Polyethylene (LDPE)

Operating Parameters

- Temperature: 4 °C to 60 °C

Sterilization Method

- Gamma Irradiation Maximum Dose: 50 KGy

Film Typical Data

|

Thickness |

- |

0.325 mm |

|

Haze |

- |

5% |

|

Water Vapor Transmission Rate |

ASTM F-1249 |

0.32 g / (m².day) at 23 °C |

|

Oxygen Transmission Rate |

ASTM D-3985 |

<0.05 cm³ / (m².day.bar) at 23 °C, 0% RH |

|

Carbon Dioxide Transmission Rate |

Mocon Permatran C-IV |

<0.2 cm³ / (m².day.bar) at 23 °C, 0% RH |

Hardware Specifications

|

Component |

Length |

Width |

Height |

Weight |

|

Trolley Base Section |

1092 mm (43.0 in.) |

821 mm (32.3 in.) |

628 mm (214.7 in.) |

30 Kg |

|

Trolley Stacking Section |

1092 mm (43.0 in.) |

821 mm (32.3 in.) |

550 mm (21.6 in.) |

13 Kg |

|

10 and 20 L Tray |

800 mm (31.5 in.) |

530 mm (20.1 in.) |

110 mm (4.3 in.) |

5.7 Kg |

|

50 L Tray |

1052 mm (41.4 in.) |

812 mm (31.2 in.) |

110 mm (4.3 in.) |

10.4 Kg |

|

Adapter for 200 and 500 L Totes |

826 mm (32.5 in.) |

541 mm (21.3 in.) |

183 mm (7.2 in.) |

3.6 Kg |

Pump Flow Rate

- Typical Pump Fow Rate During Recirculation Mixing: 13 L/min

Allegro Biocontainer Nominal Dimensions

|

Biocontainer Volume |

Max Width |

Max Length (Without Ports) |

Inlet/ Outlet Ports |

Sampling Port |

Powder Addition Port |

|

20 L |

485 mm (19.5 in.) |

738 mm (29.7 in.) |

12. 7 mm (0.5 in.) |

6.3 mm (0.25 in.) |

38mm (1.5 in.) |

|

50 L |

678 mm (27.2 in.) |

909 mm (36.5 in.) |

12.7 mm (0.5 in.) |

6.3 mm (0.25 in.) |

38mm (1.5 in.) |

Schematic Structure of Allegro Films

The powder port biocontainer has the same state-of-the-art low extractable/high transparency film structure as the standard Allegro biocontainers. The only additional material compared to the standard biocontainer range is the powder port (LDPE) to allow the addition of powders or fluids or access for sensors during operations.