Allegro™ Single-Use Mixers

High performance, easy-to-use mixers for manual to fully automated solution preparation

Point of Product

Description

High performance, easy-to-use mixers for manual to fully automated solution preparation

Mixing is a critical operation within biopharmaceutical processes for many applications, ranging from buffer and media preparation, in-process unit operations such as low pH viral inactivation, to final formulation. The Allegro single-use mixers are part of Pall’s expanding range of Allegro products and services providing integrated process solutions throughout the drug production process. The Allegro mixers combine critical requirements for single-use technologies, such as extreme ease-of-use, with established engineering principles and criteria for robust mixer design to deliver the ultimate in mixing performance.The Allegro mixers are available in 50 L, 200 L, 500 L and 1000 L sizes , in both standard and jacketed stainless steel tote formats, and can incorporate sensors (e.g. pH, conductivity and temperature) for on-line monitoring and control. Sensor signals can be handled locally on the mixer, or alternatively, can be fed directly to an existing Distributed Control System (DCS) or to an Automated Pall MVP single-use system. With the added capability of load cell integration, the Allegro mixers from Pall can be fully integrated to the Allegro MVP automated single-use systems, providing complete automated process monitoring and control solutions for all applications that require mixing (e.g pH adjustment for buffers and virus inactivation).

Product Features and Benefits

|

Feature |

Benefit |

|

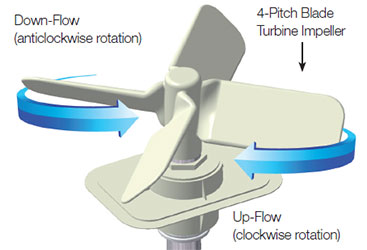

4 pitch blade impeller |

Efficient, low shear general purpose mixing over a wide range of applications and shear sensitive soluitons |

|

Impeller rotation in clockwise or counter-clockwise direction |

Flexibility to perform both up-flow and down-flow for floating (low density) and settling (high density) fluid or solids |

|

Feature |

Benefit |

|

Design principles based on existing Allegro 3D tote format for ease-of-use |

Very easy and quick to install and remove the single-use systems pre and post-use |

|

Feature |

Benefit |

|

Inflation of the mixer bag |

Provides mixing envelope for consistent performance from 50 - 1000 L and the ability to have a gas blanket in operation and mix a range of volumes |

|

Mixer Size |

200 L |

500 L |

1000 L |

|

Minimum Volume (L)* |

50 |

100 |

155 |

|

Maximum Volume (L) |

200 |

500 |

1000 |

|

Feature |

Benefit |

|

Jacketed Totes |

Temperature control in appropriate applications |

|

|

Feature |

Benefit |

|

Uses existing Allegro film with high clarity and ultra-low extractables |

Material/validation consistency across all Allegro biocontainer based systems |

|

Feature |

Benefit |

|

Optional baffles available |

To assist in reducing air entrapment at high rotation speed for sensitive molecules |

|

|

Specification

Technical Specifications

|

- |

Standard Mixer |

Jacketed Mixer |

|

Mixer Tote Part Number |

LGRMXTTE200L230B |

LGRMXJTTE200L230B |

|

Mixing volume – Max (L) |

200 |

200 |

|

Voltage (Vac) |

230 |

|

|

Current (A) |

5.1 |

|

|

Frequency (Hz) |

50 |

|

|

Motor power (kW) |

0.37 |

|

|

Impeller range (rpm) |

50 - 150 |

|

|

Mixing volume - Covering impeller (L) |

40 |

40 |

|

Mixing volume - Covering sensors/sample port (L) |

46 |

46 |

|

Gas supply (barg/psig) |

4 - 6 / 60 - 90 |

|

|

Gas connections |

SUPPLY & CABINET VENT: 10 mm Pneumatic tubing

outside diameter |

|

|

Weight - empty (kg) |

120 |

195 |

|

Weight - full (kg) |

340 |

421 |

|

Footprint* (L x W) (mm) |

785 x 615 |

785 x 615 |

|

Height (mm) |

1401 |

1401 |

|

Materials of Construction |

Standard Mixer |

Jacketed Mixer |

|

Mixer Tote Part Number |

LGRMXTTE200L230B |

LGRMXJTTE200L230B |

|

Mixer tote |

304 SS |

|

|

Mixer biocontainer (original) |

Biocontainer film; outlet port; inlet manifold & top hat: Low Density Polyethylene (LDPE); |

|

|

Mixer biocontainer (sensor biocontainer) |

Biocontainer film; inlet ports; top hat; hose barb outlet port: Low Density Polyethylene (LDPE);

|

|

*Leg centre distances

*Leg centre distances

|

- |

Standard Mixer |

Jacketed Mixer |

|

Mixer Tote Part Number |

LGRMXTTE1000L230B |

LGRMXJTTE1000L230B |

|

Mixing volume – Max (L) |

1000 |

1000 |

|

Voltage (Vac) |

230 |

|

|

Current (A) |

5.1 |

|

|

Frequency (Hz) |

50 |

|

|

Motor power (kW) |

0.37 |

|

|

Impeller range (rpm) |

50 - 150 |

|

|

Mixing volume - Covering impeller (L) |

125 |

125 |

|

Mixing volume - Covering sensors/sample port (L) |

155 |

155 |

|

Gas supply (barg/psig) |

4 - 6 / 60 - 90 |

|

|

Gas connections |

SUPPLY & CABINET VENT: 10 mm Pneumatic tubing

outside diameter |

|

|

Weight - empty (kg) |

220 |

434 |

|

Weight - full (kg) |

1320 |

1549 |

|

Footprint* (L x W) (mm) |

1360 x 1084 |

1360 x 1084 |

|

Height (mm) |

1482 |

1482 |

|

Materials of Construction |

||

|

Mixer tote |

304 SS |

|

|

Mixer biocontainer (sensor biocontainer) |

Biocontainer film; inlet ports; top hat; hose barb

outlet port: Low Density Polyethylene (LDPE); |

|

*Leg centre distances

Heat Exchange Area Estimation for Jacketed Mixer Totes

|

Mixer Capacity (L) |

Assumed Minimum Working Volume (L) |

Area Available for Heat Exchange @ Min. Working Volume (m2) |

Calculated Maximum Working Volume (L) |

Area Available for Heat Exchange @ Max. Working Volume (m2) |

|

200 |

46 |

0.49 |

200 |

1.0 |

|

500 |

100 |

0.93 |

500 |

1.8 |

|

1000 |

155 |

1.37 |

1000 |

2.9 |

Performance