Stax™ Disposable Depth Filter Systems

The Most Versatile Disposable Depth Filter Platform

Point of Product

Description

The Most Versatile Disposable Depth Filter Platform

Stax capsules, utilizing Seitz® high performance depth filter media and the patented Supradisc™ II module design, are ideally suited for demanding prefiltration and clarification biopharmaceutical applications. This ready-to-use platform is an ideal tool to streamline your process filtration applications. Stax disposable depth filter capsules increase process efficiencies and address the needs for simplicity, safety, speed, and intuitive operation. Optimized with a small foot print design, the Stax platform makes for an easy to handle and operate process step.

Scalable in size and performance to meet lab, pilot and process needs, Pall’s Stax disposable capsules enable greater flexibility and ease of use than traditional depth filter technology. With three interchangeable capsule sizes ranging from 0.25 m2 to 2.0 m2 (2.70 ft2 to 21.5 ft2). Stax capsules permit incremental increases in process fluid volume and filter area through the use of this modular design.

Simple, Intuitive Operation

Placed into one of three different sized chassis, Pall’s single use Stax capsules eliminate the use of stainless steel housings which require costly cleaning and cleaning validation. Stax system chassis are designed for assembly and use by a single operator and provide a logically conceived disposable platform in which the operator can load, operate and unload in an ergonomically designed vertical orientation. The ability to operate with two different media grades in one chassis (serial filtration) further improves the flexibility and economy of operating the Stax platform. With simple, straight forward and familiar features, the Stax platform eliminates the risk of error or mishap and enables greater process success. Integrating Pall’s Allegro™ platforms into a comprehensive

single-use system will further maximize the overall benefits of implementing a single-use strategy and the Stax platform.

|

Features |

Benefits |

|

Low hold-up volume |

Greater product recovery and lower post use rinse volume requirements than traditional modules and housings. |

|

Seamless linear scalability |

Greater flexibility and assurance of process success from <1L to 20,000+ L |

|

Minimized risk |

The Stax capsules are based upon the outstanding design of Pall’s Supradisc II modules, which provides benefits in process stability due to their high mechanical robustness. |

|

No housings |

Easier to use and manipulate while eliminating operator safety issues. |

|

Completely disposable |

Eliminates need for cleaning and cleaning validation. |

|

Encapsulated design |

Reduces operator exposure to potential biohazards. |

|

Intuitive operation |

Reduces operator training and increases time to acceptance. |

|

Small footprint |

Enables use in close proximity to other equipment and reduces cost to install. |

Minimized Risk

Benefiting from Pall’s Supradisc II mechanically robust module design, the Stax capsules provide stable filtration results batch to batch. Through the use of interlocking and welded dual drainage plates, this robust module design is able to provide the structural integrity necessary for:

-

Unobstructed process flow

-

Consistent filtration results

-

Minimized risk to filter media ruptures due toreverse pressure

-

Minimized risk of damage due to shipping and handling

Seitz depth filter media available in Stax capsules:

P-series

Seitz P-series depth filter sheets were specifically developed for the strict requirements in biotechnological and pharmaceutical industries. Manufactured with stringent in-process control methods assures consistent filtration quality, a very high purity of filter medium, and alignment with the requirements of the pharmaceutical industry. For further information, please reference Pall data sheet USD 2205 or validation guide USTR 2366.

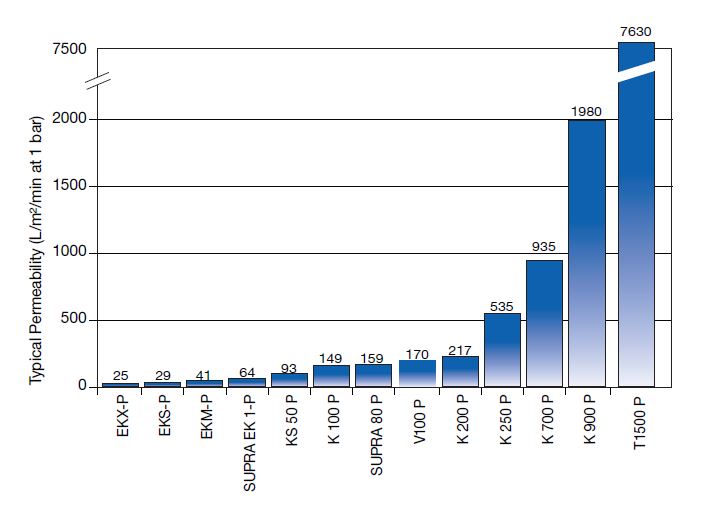

Permeability - P-series

Seitz HP-series depth filter sheets are comprised of two distinct layers of Seitz P-series depth filter sheets; a coarser layer upstream followed by a finer layer downstream. These performance-enhanced depth filter sheets have been designed for use in low viability, high solids containing applications. As small shifts in process conditions can cause dramatic differences in filtration requirements, the flexibility of combining any combination of P-series media in an HP format allows for improved process optimization. For further information, please reference Pall data sheet USD 2335 or validation guide USTR 2404.

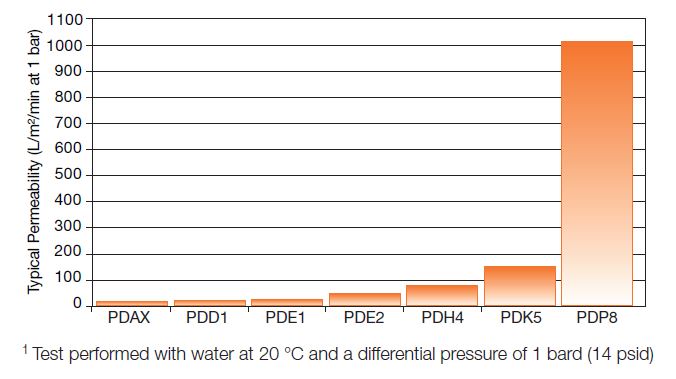

Permeability - HP-series1

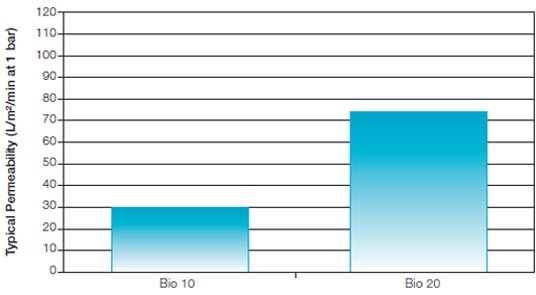

Seitz Bio-series depth filter sheets are specially developed from highly purified natural and modified cellulose fibers and contain no inorganic materials such as diatomaceous earth (DE), perlite or glass fibers. The lack of these inorganic substances significantly reduces the levels of ash and heavy metal extractables. For further information please reference Pall data sheet USD 2201.

Permeability

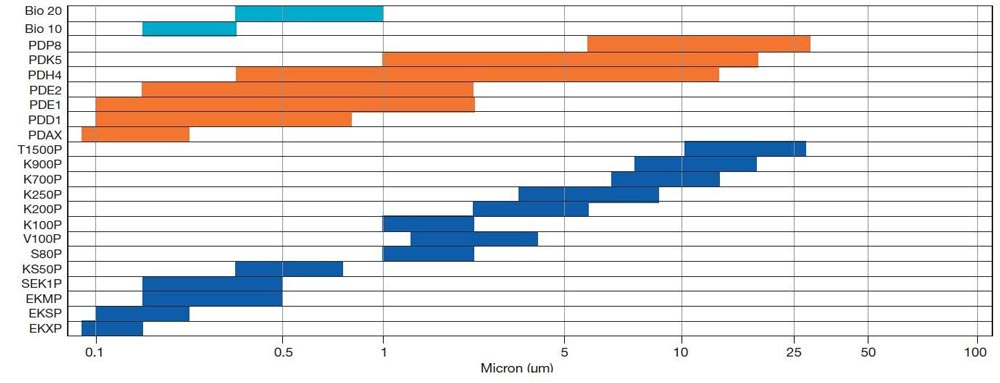

Nominal Retention Rating of Seitz P-series, HP-series and Bio-series Depth Filter Sheet Media

Dual-Layer Filter Media Grade Combinations

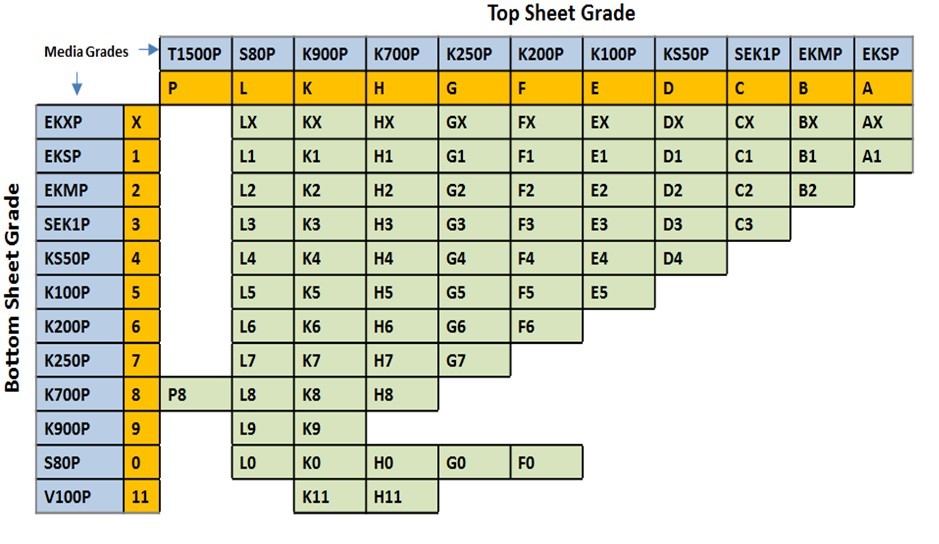

A dual layer media grade is a combination of two single layer media grades. The media grade code starts with P (Pharmaceutical Grade) followed by D (Dual layer) and the appropriate dual media combination ID. For generating a dual media combination ID, the appropriate top sheet grade letter (columns) is combined with the bottom sheet grade number or “x” (lines).

Specification

Filter Area

|

Capsule Size |

Capsule Footprint SizeDiameter |

Height |

|

Small |

0.5 m2 (5.38 ft2)

|

0.25 m2 (2.70 ft2) |

|

Medium |

1.0 m2 (10.8 ft2)

|

0.5 m2 (5.38 ft2)

|

|

Large |

2.0 m2 (21.5 ft2)

|

1.0 m2 (10.8 ft2) |

Capsule Dimensions

|

Capsule Size |

Capsule Footprint SizeDiameter |

Height |

|

Small |

442 mm (17.4 in.) |

58.5 mm (2.3 in.) |

|

Medium |

442 mm (17.4 in.) |

80.8 mm (3.2 in.) |

|

Large |

442 mm (17.4 in.) |

128.8 mm (5.1 in.) |

Capsule Weight

|

Capsule Size |

Weight Dry |

Wet (post blow down) |

|

Small |

3.45 - 3.8 kg |

4.8 - 5.25 kg |

|

Medium |

4.9 - 5.3 kg |

7.6 - 8.0 kg |

|

Large |

7.0 - 8.2 kg |

12.7 - 13.6 kg |

Void Volume

|

Component |

Void Volume 2 |

|

Small Capsule |

1.1 L |

|

Medium Capsule |

1.6 L |

|

Large Capsule |

2.6 L |

Maximum Operating Pressure

- 3.5 bar (50 psi) at 25 ºC

- 1.0 bar (14.3 psi) at 60 ºC

Note: All pressure specifications are for capsules correctly installed into Pall Stax chassis

-

2.4 bar (35 psi) at 25 ºC - forward direction

-

60 ºC

Inlet and Outlet Dimensions (Distribution Manifold)

-

50.8 mm (2 in.) Tri-clamp

-

2 autoclave cycles: 60 minutes at 125 ºC

Post Use Autoclave Sterilization

-

60 minutes at 121 ºC (applies to entire Stax system - capsules and chassis together)

Sanitization

|

Hot water sanitization |

80 °C at 1 bar (14.3 psifor 60 minutes |

|

Post use caustic treatment |

1 M NaOH at 3.5 bar (50 psi)for 60 minutes at 25 °C |

Traceability

-

Capsule part number laser engraved with the following:

-

Media batch number

-

Internal sales order number

-

Unique serial number

-

Capsule Materials of Construction

|

Capsule shell |

Glass filled polypropylene |

|

Manifold assemblies |

Glass filled polypropylene |

|

5-to-1 manifold |

Glass filled polypropylene |

|

Internal module |

Polypropylene |

|

Gasket |

Silicone |

|

Depth filter media |

See specific filter media data sheet |

For further information regarding extractables data and certifications for the capsules and manifolds please reference the Stax platform validation guide USTR 2528

|

Footprint Size |

|||

|

Chassis Model |

Height |

Footprint Size Length |

Width |

|

SXLSC02 |

1018 mm (40.0 in.) |

516 mm (20.3 in.) |

516 mm (20.3 in.) |

|

SXPSC05P |

1241 mm (48.9 in.) |

610 mm (24.0 in.) |

610 mm (24.0 in.) |

|

SXPSC05W |

1312 mm (51.6 in.) |

1150 mm (45.3 in.) |

800 mm (31.5 in.) |

|

SXPSC10P |

1864 mm (73.4 in.) |

610 mm (24.0 in.) |

610 mm (24.0 in.) |

|

SXPSC10W |

1935 mm (76.2 in.) |

1150 mm (45.3 in.) |

800 mm (31.5 in.) |

Chassis Weights

|

Chassis Model |

Weight |

|

SXLSC02 |

75 kg |

|

SXPSC05P |

190 kg |

|

SXPSC05W |

192 kg |

|

SXPSC10P |

238 kg |

|

SXPSC10W |

240 kg |

Capacity - Maximum Number of Capsules

|

Chassis Model |

Small Capsule |

Medium Capsule |

Large Capsule |

|

SXLSC02 |

4 |

3 |

2 |

|

SXPSC05* |

10 |

7 |

5 |

|

SXPSC10* |

22 |

16 |

10 |

- The table above indicates the total number of capsules in various sizes that each chassis size can accommodate.

- It is also possible to make combinations of different sized capsules to achieve the exact filtration area required to the nearest 0.25 m2 DL (0.5 m2 SL) [2.70 ft2 DL (5.38 ft2 SL)]

- It is also possible to operate any of the three chassis with as few as (1) of the smallest capsules 0.25 m2 DL (0.5 m2 SL) [2.70 ft2 DL (5.38 ft2 SL)]

|

Chassis Model |

Filtration Area |

|

SXLSC02 (single layer media) |

0.5 - 4 m2 (5.38 - 43.1 ft2) |

|

SXLSC02 (double layer media) |

0.25 - 2 m2 (2.70 - 21.5 ft2) |

|

SXPSC05 * (single layer media) |

0.5 - 10 m2 (5.38 - 107.6 ft2) |

|

SXPSC05 * (double layer media) |

0.25 - 5 m2 (2.70 - 53.8 ft2) |

|

SXPSC10 * (single layer media) |

0.5 - 20 m2 (5.38 - 215.3 ft2) |

|

SXPSC10 * (double layer media) |

0.25 - 10 m2 (2.70 - 107.6 ft2) |

Chassis Materials of Construction

-

304/1.4301 Stainless Steel 1.2 μm / 64 μin Ra (typical) Electro-polish

Design Basis

-

Conforms to Pressure E quipment Directive – Category 1 / Module A (SXLSC02 is Sound Engineering Practice)

-

Outside scope of ASME VIII Div 1

-

Complies with Universal Building Code (1997) – Zone 4 / Importance factor 1.25 (SXPSC** P ONLY)